Multi-use robots support smart manufacturing systems

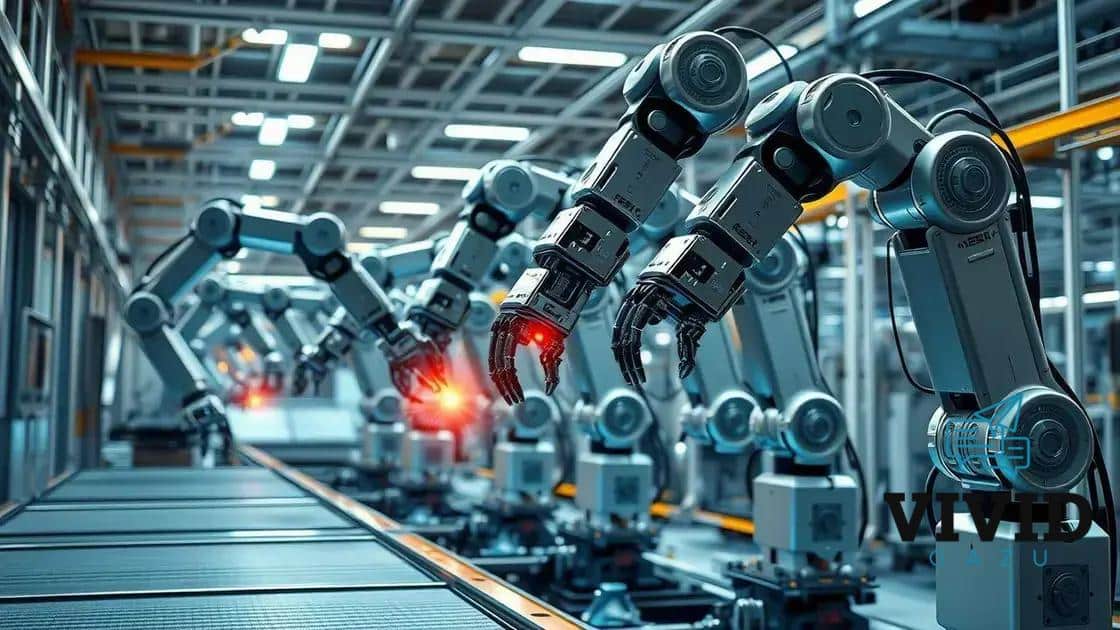

Multi-use robots support smart manufacturing systems by enhancing flexibility and efficiency, enabling faster production cycles, and optimizing workflow while reducing operational costs and waste.

Multi-use robots support smart manufacturing systems by enhancing flexibility and efficiency on the factory floor. Have you ever wondered how these robots can change the game for productivity?

Understanding multi-use robots in manufacturing

Understanding multi-use robots in manufacturing is essential for companies looking to innovate and enhance their production capabilities. These robots are designed to perform various tasks, making them highly adaptable in different settings. As industries evolve, the role of these robots becomes increasingly important.

What are multi-use robots?

Multi-use robots are automated machines that can handle multiple tasks within the manufacturing process. Unlike traditional robots, which are often specialized for a single function, multi-use robots can switch between roles seamlessly. This flexibility leads to greater efficiency and productivity.

Benefits of multi-use robots

- Cost-effective: They reduce the need for multiple machines, lowering operational costs.

- Adaptability: Multi-use robots can be programmed for different tasks, accommodating various production needs.

- Increased efficiency: With faster task switching, production lines can operate during more hours with less downtime.

Moreover, adopting multi-use robots helps manufacturers respond quickly to market changes. As product demands shift, these robots can adapt without significant reconfiguration. This not only saves time but also reduces the risk of errors.

Investing in multi-use robots also provides a significant edge in the competitive manufacturing landscape. As companies strive to maintain efficiency and minimize costs, the versatility offered by these robots enables them to do just that. Implementing advanced robotic systems can lead to streamlined processes and better overall performance.

In summary, multi-use robots represent a powerful asset in modern manufacturing. Their ability to perform various functions efficiently makes them vital for any manufacturer aiming to stay ahead.

Advantages of implementing multi-use robots

Implementing multi-use robots in manufacturing comes with numerous advantages that boost productivity and efficiency. These versatile machines can perform various tasks without the need for extensive reconfiguration, making them a valuable asset for manufacturers.

Enhancing productivity

One of the most significant advantages is the ability to enhance productivity. Multi-use robots can operate continuously, allowing for longer production runs without the need for breaks. This leads to increased output and helps meet growing market demands.

Flexibility in operations

Another benefit is their flexibility. Multi-use robots can be easily reprogrammed to handle different tasks as production needs change. This adaptability enables manufacturers to quickly respond to variety in product demands while minimizing downtime.

- Reduced operational costs: By using one robot for multiple tasks, companies can save on maintenance and operational expenses.

- Space efficiency: Fewer machines mean that factories can save valuable floor space.

- Improved safety: Robots can take on dangerous tasks, reducing the risk of workplace injuries for human employees.

Moreover, multi-use robots allow for consistent and precise execution of tasks. This precision leads to higher quality products and less waste. As these robots take over repetitive and strenuous work, human workers can focus on more complex and creative tasks.

The integration of multi-use robots can also foster innovation within the manufacturing process. With the ability to quickly adapt to new processes or products, businesses are better equipped to implement new technologies and methods. This keeps them competitive in an ever-evolving market.

Challenges in integrating multi-use robots

Integrating multi-use robots into manufacturing processes can bring significant benefits, but it also presents several challenges that companies must address. These challenges can range from technical issues to workforce adaptation, making careful planning essential.

Technical obstacles

One of the main challenges is the technical complexity involved in implementing these systems. Multi-use robots often require advanced programming and software to handle various tasks. This means that companies must invest in high-quality training for their staff to ensure efficient use of the robots.

Workforce integration

Another significant hurdle is adapting the existing workforce to a robotic environment. Employees may feel threatened by automation and resist its implementation. It is crucial for management to foster a culture of collaboration between humans and robots. Educating workers about the benefits of these technologies can help ease fears and improve acceptance.

- Change management: Organizations may need to adjust to new workflows and processes.

- Maintenance challenges: Multi-use robots require regular maintenance, which can add to operational costs.

- Error management: Initial integration can lead to mistakes as the technology is fine-tuned.

Furthermore, compatibility issues between different types of robots and existing systems can complicate integration. Companies should conduct thorough assessments to ensure the new robotics systems can communicate effectively with their current machinery. This helps to ensure smooth transitions and optimal performance.

The duration of the integration process can also be daunting. Depending on the complexity of the operations, it might take significant time to see the full benefits of integrating multi-use robots. Companies must remain patient during this period and provide ongoing support to their teams.

Real-world applications of multi-use robots

Real-world applications of multi-use robots showcase their versatility and capability across various industries. These robots are transforming operations in manufacturing, logistics, healthcare, and more. By examining different sectors, we can see how they effectively contribute to efficiency and productivity.

Manufacturing

In the manufacturing sector, multi-use robots are employed for tasks like assembly, painting, and packaging. Their ability to quickly switch between tasks enables factories to optimize production lines without significant downtime. For instance, a single robot can assemble components, then immediately change to packaging finished products. This adaptability helps reduce costs and increase operational speed.

Logistics and warehousing

In logistics and warehousing, multi-use robots assist with inventory management and order fulfillment. These robots can navigate warehouses, retrieve items, and transport them to packing stations, optimizing space and minimizing labor costs. They can be programmed to handle various tasks, making them an integral part of modern supply chains.

- Enhanced accuracy: Robots reduce human error in picking and packing processes.

- Increased flexibility: Automated systems can adjust to changing inventory demands seamlessly.

- Improved efficiency: Robots work around the clock, ensuring swift operations.

Healthcare is another area benefiting from multi-use robots. In hospitals, these robots can assist with drug dispensing, patient monitoring, and even surgical procedures. They enable healthcare professionals to focus on patient care while ensuring tasks that require precision are performed reliably. Innovations in robotic technology allow for enhanced outcomes in surgeries, leading to quicker recovery times for patients.

Additionally, the agricultural industry has started to utilize multi-use robots for planting, harvesting, and monitoring crops. These robots increase yield and reduce labor-intensive tasks, making agriculture more sustainable. By combining multiple functions into one robot, farmers can save time and resources, fostering a more efficient agricultural process.

Future trends in smart manufacturing systems

The future trends in smart manufacturing systems are driving changes that enhance efficiency and productivity. Technologies like artificial intelligence (AI), the Internet of Things (IoT), and advanced robotics are shaping the landscape of manufacturing.

AI and machine learning

AI and machine learning will play a crucial role in optimizing manufacturing processes. By using data analytics, manufacturers can predict maintenance needs, reduce downtime, and improve overall equipment effectiveness. This predictive approach enables factories to operate more smoothly while minimizing costs.

Internet of Things (IoT)

The IoT is another significant trend transforming manufacturing. With smart sensors, machines can communicate and share data in real-time. This connectivity allows for better monitoring and control of production lines, enabling faster responses to any anomalies. As a result, companies can enhance their operational performance and improve product quality.

- Increased automation: More processes will become automated, further reducing the need for manual labor.

- Data integration: Collecting and analyzing data from multiple sources will streamline decision-making.

- Customization: Smart systems will allow for greater customization in products to meet specific market demands.

Advanced robotics will also continue to evolve. Future robots will be more collaborative, working alongside human employees to enhance production without replacing jobs. This collaborative approach ensures that workers can focus on tasks requiring creativity and strategic thinking while robots handle repetitive tasks.

Additionally, sustainability will be at the forefront of future manufacturing trends. Companies will seek to reduce waste and carbon footprints by adopting greener practices and technologies. This shift not only meets consumer demands for environmentally friendly products but also contributes to cost savings in the long run.

FAQ – Frequently Asked Questions about Multi-use Robots in Smart Manufacturing

What are multi-use robots?

Multi-use robots are automated machines designed to perform various tasks in manufacturing, increasing flexibility and efficiency.

How do multi-use robots improve productivity?

They enhance productivity by operating continuously and quickly switching between tasks, reducing downtime in production.

What challenges are faced when integrating multi-use robots?

Challenges include technical complexities, workforce adaptation, and ensuring compatibility with existing systems.

What future trends are expected in smart manufacturing?

Future trends include increased automation, AI and IoT integration, sustainability efforts, and greater collaboration between robots and humans.